Product Description

Straight coupling half heart necklace long distance couples ring wedding stainless steel watch minimal matching couple outfits magnet bracelet key roller chain

Application of Straight coupling

Straight couplings are used to connect 2 pieces of pipe together end to end. They are made up of 2 halves that are joined together by bolts or other fasteners. Straight couplings are available in a variety of materials, including steel, aluminum, and plastic. They are also available in various sizes, to accommodate different pipe sizes.

Straight couplings are used in a variety of applications, including:

- Plumbing: Straight couplings are used in plumbing to connect pipes together. They are used in a variety of applications, including water supply, waste disposal, and gas distribution.

- HVAC: Straight couplings are used in CHINAMFG to connect pipes together. They are used in a variety of applications, including air conditioning, heating, and ventilation.

- Oil and gas: Straight couplings are used in oil and gas to connect pipes together. They are used in a variety of applications, including pipelines, storage tanks, and refineries.

- Chemical processing: Straight couplings are used in chemical processing to connect pipes together. They are used in a variety of applications, including reactors, distillation columns, and storage tanks.

- Other: Straight couplings are used in various other applications, including manufacturing, construction, and agriculture.

Straight couplings are a versatile and reliable way to connect 2 pieces of pipe together. They are available in a variety of materials, sizes, and applications.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

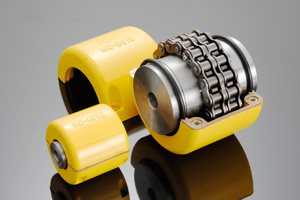

Roller Chain Couplings for Heavy Machinery and Industrial Conveyors

Yes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems.

The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads.

Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation.

When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Roller Chain Couplings in Applications Requiring Frequent Starts and Stops

Yes, roller chain couplings can be used in applications that require frequent starts and stops. These couplings are designed to provide reliable torque transmission and accommodate misalignments even during repetitive and rapid motion changes.

The key features that make roller chain couplings suitable for such applications include:

- Durable Construction: Roller chain couplings are typically constructed from high-quality materials, such as steel or stainless steel, which offer excellent durability and resistance to wear and fatigue.

- Shock Absorption: The flexible nature of roller chain couplings allows them to absorb shocks and vibrations that may occur during frequent starts and stops, preventing damage to connected equipment.

- Backlash Minimization: Roller chain couplings are designed to minimize backlash, which is the amount of free play between the connected shafts. This feature ensures precise and reliable torque transmission, even when starting and stopping repeatedly.

- Smooth Operation: The chain and sprocket design of roller chain couplings allows for smooth operation, reducing jarring movements during starts and stops.

- Misalignment Tolerance: Roller chain couplings can accommodate angular and parallel misalignments between shafts, which is essential in applications where frequent starts and stops may lead to slight shifts in the alignment.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain, making them suitable for applications requiring frequent operation. Regular inspection and lubrication can help ensure optimal performance.

It is important to select the appropriate size and type of roller chain coupling based on the specific requirements of the application, including the expected frequency of starts and stops. Proper maintenance and monitoring of the coupling’s condition can help prolong its lifespan and ensure smooth operation even in demanding applications with frequent motion changes.

Accommodating Misalignment and Reliable Torque Transmission in Roller Chain Couplings

Roller chain couplings are designed to accommodate misalignment and provide reliable torque transmission in mechanical power transmission systems. They achieve this through the following features:

- Elongated Holes: The roller chain coupling’s hubs have elongated holes that allow for angular misalignment between the connected shafts. These holes provide flexibility and prevent excessive stress on the coupling and connected equipment.

- Roller Chain Design: The roller chain used in the coupling is a flexible and robust component that can transmit torque even in situations with slight misalignment. The design of the roller chain ensures smooth engagement and disengagement of the sprockets, reducing wear and power loss.

- Tension Adjustment: Roller chain couplings typically have an adjusting mechanism that allows for tensioning the chain. Proper tensioning is crucial for maintaining efficient torque transmission and preventing slippage.

- Single or Double Roller Chain: Some roller chain couplings come with a double roller chain design, which increases the torque capacity and allows for higher misalignment compensation.

- Torsionally Rigid Coupling: While roller chain couplings can accommodate misalignment, they still provide torsional rigidity, ensuring efficient power transmission without significant losses.

By allowing for misalignment while maintaining reliable torque transmission, roller chain couplings are well-suited for various power transmission applications, including those where slight misalignment is unavoidable or expected.

editor by CX 2024-04-25

by

Tags:

Leave a Reply