Product Description

Product Description

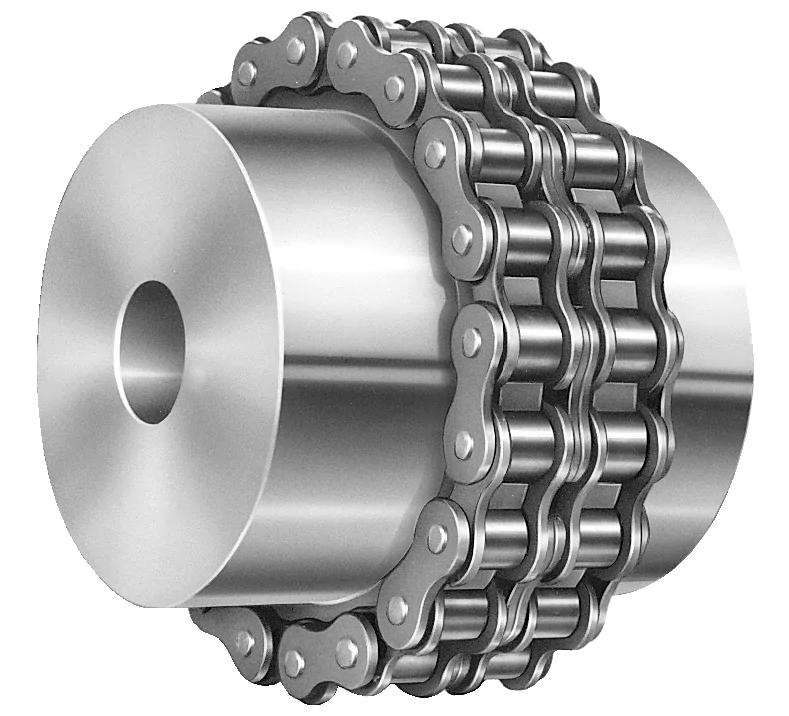

Hot Selling GL Type Spline Rigid Shaft Couplings Roller Chain Coupling For Industry Machine

FEATURES

Manufactured according to relevant industrial standards

Available in many sizes, ratings, and product types, including flexible shaft couplings and OK couplings

Fabricated from a variety of high-grade steel

BENEFITS

Several surface treatment processes protect against corrosion

Customized products are available

Large couplings withstand very high torque

Flexible shaft couplings compensate for shaft misalignment

The chain coupling consists of two-strand roller chains, 2 sprockets and AL-Alloy cover, features simple and compact structure, and high flexibility, power transmission capability and durability.

What’s more ,the chain coupling allows simple connection/disconnection, and the use of the housing enhances safety and durability.

Advantages:

1. Material: C45 steel, Aluminum, Rubber and plastic etc.

2. High efficiency in transmission

3. Finishing: blacken, phosphate-coat, and oxidation.

4. Different models suitable for your different demands

5. Application in wide range of environment.

6. Quick and easy mounting and disassembly.

7. Resistant to oil and electrical insulation.

8. Identical clockwise and anticlockwise rotational characteristics.

9. Small dimension, low weight, high transmitted torque.

10. It has good performance.

| Partnerships Reliable Supply-Chain: |

Based on our experienced team and strict, effective supply chain management, Granville products deliver premium quality, and performance our customers have relied on for years. From a full range of bearings, mounted bearing units, power transmission products, and related markets around the world, we provide the industry’s most comprehensive range of qualified products available today.

Advantage Manufacturing Processesand Quality Control:

01 Heat Treatment

02 Centerless Grinding Machine 11200 (most advanced)

03 Automatic Production Lines for Raceway

04 Automatic Production Lines for Raceway

05 Ultrasonic Cleaning of Rings

06 Automatic Assembly

07 Ultrasonic Cleaning of Bearings

08 Automatic Greasing, Seals Pressing

09 Measurement of Bearing Vibration (Acceleration)

10 Measurement of Bearing Vibration (Speed)

11 Laser Marking

12 Automatic Packing

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Standard Sizes and Specifications of Roller Chain Couplings

Roller chain couplings come in various sizes and specifications to accommodate a wide range of mechanical power transmission applications. The standard sizes and specifications of roller chain couplings typically include:

- Chain Size: Roller chain couplings are available in different chain sizes, such as 40, 50, 60, 80, 100, etc. The chain size indicates the pitch of the roller chain used in the coupling.

- Torque Capacity: The torque capacity of a roller chain coupling varies based on its size and design. Manufacturers provide torque ratings that specify the maximum amount of torque the coupling can handle without failure.

- Speed Rating: Roller chain couplings have a maximum speed rating, which indicates the highest rotational speed at which the coupling can operate safely and efficiently.

- Material: Roller chain couplings are commonly made from materials such as carbon steel, stainless steel, or nickel-plated steel, providing different levels of strength, corrosion resistance, and durability.

- Hub Type: Roller chain couplings may come with different hub types, such as pilot bore hubs or taper bore hubs, to suit various shaft connections.

- Number of Teeth: Some roller chain couplings have specific tooth configurations that can affect their performance and backlash characteristics.

- Misalignment Capacity: Manufacturers specify the maximum allowable misalignment (angular and parallel) that the coupling can accommodate to ensure reliable operation.

It is essential to refer to the manufacturer’s catalogs or product specifications to determine the exact sizes and specifications available for specific roller chain couplings. Selecting the right size and specifications depends on the application’s requirements, including torque, speed, misalignment, and environmental conditions.

Materials Used in Manufacturing Roller Chain Couplings

Roller chain couplings are typically constructed from high-quality materials to ensure durability and reliable performance. The most common materials used in their manufacturing include:

- Steel: Steel is a popular choice for roller chain couplings due to its excellent strength and resistance to wear. It can handle high torque and speed requirements, making it suitable for a wide range of industrial applications.

- Stainless Steel: Stainless steel is used when corrosion resistance is required. It is often employed in industries where the coupling is exposed to moisture, chemicals, or harsh environmental conditions.

- Cast Iron: Cast iron is known for its robustness and excellent heat dissipation properties. It is commonly used in applications where shock absorption and reduced vibrations are essential.

- Aluminum: Aluminum is a lightweight material that offers good strength-to-weight ratio. It is commonly used in applications where reducing the overall weight of the system is critical.

- Nickel-Plated: Nickel-plated roller chain couplings provide enhanced corrosion resistance, making them suitable for applications in challenging environments.

When selecting a roller chain coupling, it is essential to consider the specific requirements of the application, including torque, speed, environment, and potential exposure to corrosive substances. Choosing the right material ensures the coupling’s longevity and efficient power transmission in the intended operating conditions.

Torque and Speed Limits for Different Roller Chain Coupling Designs

The torque and speed limits of roller chain couplings can vary depending on their specific designs and construction materials. Some common factors that influence these limits include:

- Coupling Size: Larger roller chain couplings generally have higher torque and speed ratings compared to smaller ones.

- Construction Material: Couplings made from high-strength materials, such as stainless steel or hardened steel, can handle higher torques and speeds than those made from standard steel or other materials.

- Number of Strands: Roller chain couplings with multiple strands of roller chain can handle higher torques compared to single-strand designs.

- Operating Environment: The operating environment, including ambient temperature, humidity, and presence of contaminants, can affect the torque and speed capabilities of the coupling.

It is crucial to consult the manufacturer’s specifications and guidelines for each roller chain coupling model to determine its specific torque and speed limits. Exceeding the recommended torque and speed ratings may lead to premature wear, reduced efficiency, or even catastrophic failure of the coupling and connected equipment.

When selecting a roller chain coupling, it is essential to consider the application’s torque and speed requirements and choose a coupling that comfortably operates within those parameters. If the application demands high torques or speeds, it may be necessary to opt for larger or more robust coupling designs or explore alternative coupling types that better suit the specific requirements.

editor by CX 2024-04-12

Leave a Reply