Product Description

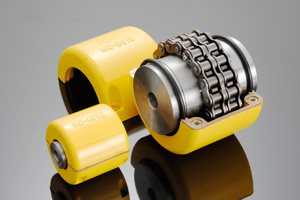

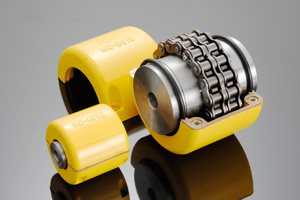

CHAIN COUPLING

Chain couplings are used for textile, agricultural machinery, lifting transporation, engineering, mining, light industry, chemical industry and other mechanical transmission shaft, suitable for high temperature, wet and dusty conditions, but not suitable for high-speed, sevious impact loading and axial force transmission occasions.

. Production Description

More Couplings

Other transmission products:

Roller Chain, Sprocket, V Pulley, Timing Pulley, Coupling, Gear Rack, Ball Bearing, Pillow Block Bearing

Packing and Delivery

FAQ

1. Can I get any sample ?

Samples are free to be available, if there is any in stock. But you have to absorb the relative courier fee.

2. How long is the delivery time for the production?

Production lead time is 30-60 days for the production.

3. What’s your advantage?

Competitive price, good quality, high-experience engineers abailable /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Roller Chain Couplings for Heavy Machinery and Industrial Conveyors

Yes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems.

The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads.

Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation.

When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Reducing Vibrations and Ensuring Smooth Operation with Roller Chain Couplings

Roller chain couplings are designed to provide a flexible and torsionally soft connection between shafts, which helps in reducing vibrations and ensuring smooth operation in mechanical power transmission systems. Here’s how roller chain couplings contribute to achieving these benefits:

- Shock Absorption: Roller chain couplings have the ability to absorb and dampen shock loads that may occur due to sudden starts, stops, or changes in the load. This feature prevents the transmission of these shocks to connected equipment, reducing vibrations and protecting the system from mechanical damage.

- Torsional Flexibility: The flexibility of roller chain couplings allows for slight misalignments between shafts. This capability helps in accommodating minor misalignments, which might otherwise lead to increased vibrations and noise in rigid coupling systems.

- Uniform Load Distribution: Roller chain couplings distribute the transmitted torque uniformly along the chain, reducing stress concentration on specific components. This even distribution of load helps in maintaining smooth operation and prolonging the life of the coupling.

- Damping Properties: The material properties of roller chain couplings, such as the use of elastomeric or plastic elements in some designs, provide inherent damping characteristics. This damping helps in absorbing vibrations and preventing resonance, ensuring stable and smooth operation.

- Reduced Backlash: Roller chain couplings exhibit minimal backlash due to the precise fit of the chain’s teeth with the sprockets. This feature is beneficial in applications that require accurate positioning and motion control.

By reducing vibrations and ensuring smooth operation, roller chain couplings contribute to improved overall system performance, reduced wear and tear on components, and enhanced reliability in various industrial applications.

How to Select the Right Roller Chain Coupling for Specific Machinery or Equipment?

Selecting the right roller chain coupling for specific machinery or equipment involves considering several important factors. Here’s a step-by-step guide:

- Torque Requirements: Determine the torque that the coupling needs to transmit between the driving and driven shafts. This will help you choose a coupling with the appropriate torque capacity for your application.

- Speed: Consider the operating speed of the machinery. Higher speeds may require special high-speed roller chain couplings designed to handle the centrifugal forces.

- Misalignment: Evaluate the degree of misalignment between the shafts. Different roller chain couplings have varying misalignment capabilities, so choose one that can accommodate the misalignment in your application.

- Space Constraints: Measure the available space for the coupling. Some roller chain couplings are compact and may be suitable for applications with limited space.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to contaminants. Choose a coupling material and finish that can withstand the environmental conditions.

- Load Characteristics: Assess the nature of the loads and any shock or vibration present in the system. For heavy-duty or shock-loaded applications, consider using heavy-duty roller chain couplings.

- Alignment Maintenance: Evaluate the ease of alignment maintenance. Some couplings may require more frequent checks and adjustments to maintain proper alignment.

- Backlash: Determine the level of backlash permissible in the application. Certain couplings may introduce minimal backlash, which is critical in precision systems.

- Cost: Consider the overall cost, including the initial purchase price and long-term maintenance expenses. Opt for a roller chain coupling that provides the best value for your specific needs.

By carefully considering these factors, engineers and designers can identify the most suitable roller chain coupling that ensures reliable and efficient power transmission for their machinery or equipment.

editor by CX 2024-04-10

by

Tags:

Leave a Reply