Roller drive

This specification is an ultra-wearable limiter, suitable for those working conditions that require frequent disengagement

Can single point reset or 360°equidistant 30° 45° 60° re-engagement

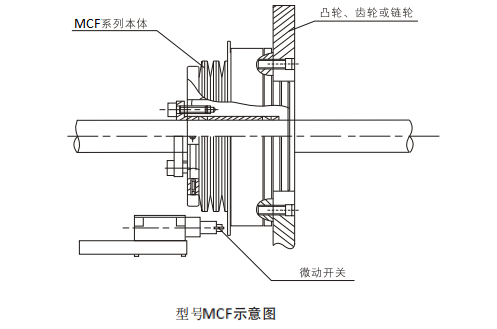

Drive disconnection can be realized by electromechanical switch/proximity switch

Compared with electronic systems, the device can directly intervene, and the response capability is improved. No maintenance, long service life, high stability

Suitable for working in humid and oily environment

On request

Equipped with a complete set of transmission gears, all turned and assembled (sprockets, pulleys, gear pairs)

For low intervention torques, coil springs can be used

Connected by opening and keyway or expansion sleeve

A half coupling can be added to realize the transmission between shaft and shaft (for this specification, if coupling parameters are required

The torque limiter uses rollers to achieve motion transmission. When the set torque is reached, the overload slips. At the same time, it can be equipped with a proximity switch or a mechanical switch to detect the overload displacement and output an electrical signal. It is suitable for use in environments that require frequent disengagement, such as automatic screwing. Screw machine, capping machine, etc.