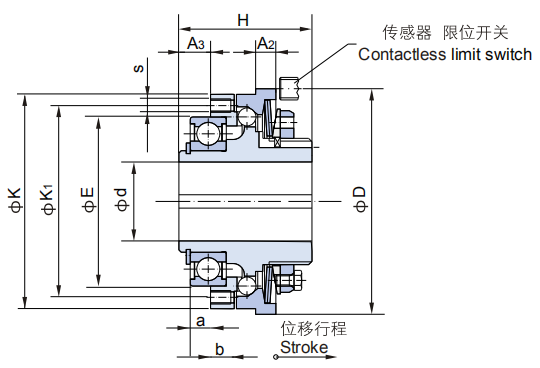

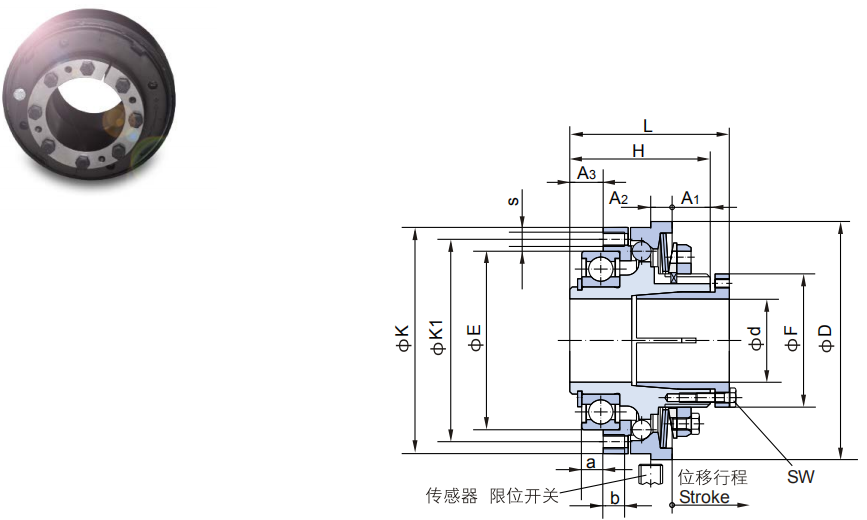

Through balancing the nut to perform precise adjustment

The torque limiter is equipped with a scale meter, which is convenient for torque adjustment

Re-reset at equal intervals or 360°

No maintenance

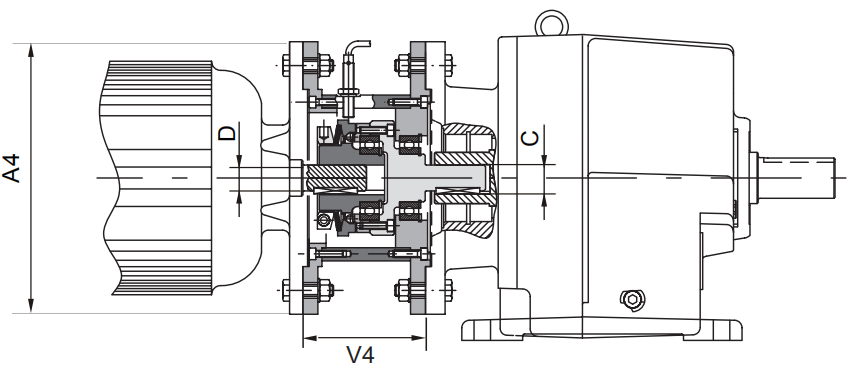

Can be equipped with fine-tuning mechanical switch/proximity switch to stop the motor drive, the assembly drive assembly is directly supported by roller bearings

on request:

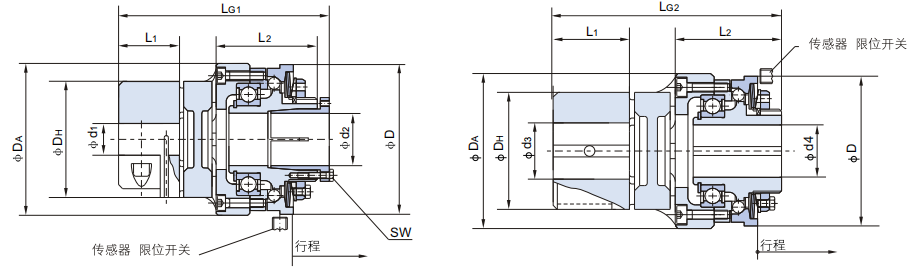

Equipped with a complete set of transmission components assembly (sprockets, pulleys, gears...)

Can be connected through 8 holes, the component can be circulated with other products on the market

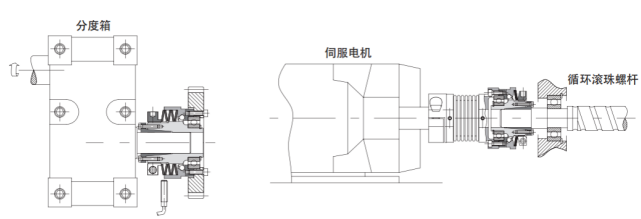

Equipped with connecting flange to connect with the most common intermittent drive unit

Mesh can be customized to stage 30 °, 45 °, 60 °, 90 °,..

The Backlash-free torque limiter has high technology and high accuracy. A backlash-free motion transmission is provided through a highly sensitive reaction action, which can be released instantly after reaching the set release torque.

main application

Bottle blowing machines, filling machines

labeling machines and other packaging machinery

CNC tool machinery, indexing table

Director, powertrain

Servo motor, guide rail

advantages and features

Protect the product in case of overload

Protect the indexing device when the transmission is overloaded

In the event of a collision, protect the mechanical operating unit

In case of collision or limit stop, protect the slide rail or servo motor